Manufacturing Revolutionized by Predictive Analytics

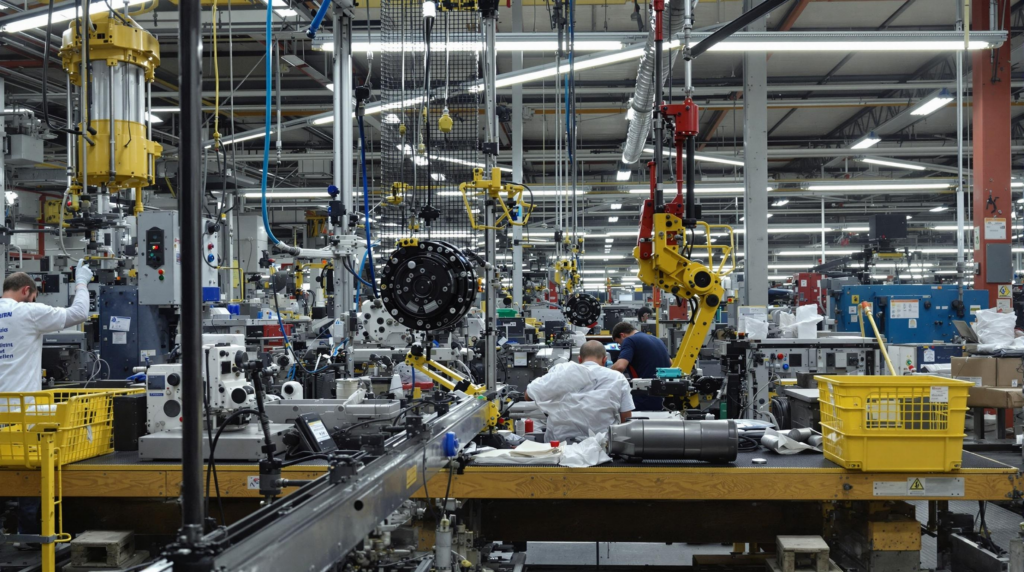

To stay ahead of the competition globally and in a fast changing market, the adoption of advanced technologies offers chances of transformation. Accept voids which predictive analytics does looking into deeply. Advanced technologies such as, predictive modeling, algorithms, and even regression analysis allow a company to use historical data to avert unwanted events from happening. New technologies alone cannot be implemented; reorganizing how processes are done and how decisions are made is also necessary. Predictive analytics is one concept every manufacturer who wants operational efficiency and business excellence should learn. This article describes the importance of analytics in manufacturing processes.

The primary objective of predictive analytics is to look forward and make an educated guess about the future based on data collected. These days, manufacturers are able to gather tremendous data from the supply chain, production lines and even from machinery, which, with the right approach, can be very helpful. Implementing mathematical models on this data can offer estimates of possible equipment failure, expected change in consumer demand and various operational parameters. The end result is efficient, quality manufacturing processes. Predictive analytics will enhance the operational framework of the business by making it possible to proactively solve problems, which enables the establishment of proactive decision making.

Understanding Predictive Analytics

As stated before, predictive analytics encompasses several methods, which enable forecasting by examining the data within the manufacturing domain. The very first stage requires pre-qualification of the phase in which there is an active process of gathering data, such as data from the sensors mounted on the machines, data manually entered by the employees, and historical data about the production. The data compilation goes through a checking stage where sophisticated algorithms are used to evaluate the data and information is extracted on possible patterns and trends that can be used for decision making in the future.

Moreover, the real application of these results is task prediction. Manufacturers can foresee the periods when active maintenance should be done, thus enabling proactive maintenance to be done in a way that minimizes operation down times and maximizes production output. Also, the predictive models can assist in understanding inventory and consumer trends as well as enhancing more efficient distribution and inventory planning. In the long term, predictive analytics improves the intelligent responsive manufacturing system where the users could easily respond to the new market conditions.

Benefits of Predictive Analytics in Manufacturing

Including predictive analysis in manufacturing approaches is useful and uplifting too. Here are a few key benefits:

- Increased Efficiency: By accurately forecasting machine failures and maintenance requirements, manufacturers can perform repairs proactively, drastically reducing unplanned downtime.

- Cost Savings: Enhanced inventory management through predictive modeling leads to reduced operational costs and minimizes the risk of excess inventory.

- Enhanced Product Quality: Continuous monitoring of production quality through data insights allows manufacturers to identify and rectify defects in real-time.

Each single advantage considerably contributes to the profits earned by the manufacturer. Consider, for instance, the savings associated with reduced downtime. While it saves time, it also optimizes the expenditure of labor and other recources. The high fusion of such analytics could offer a powerful competitive edge in a highly contested market.

Real-World Applications of Predictive Analytics

Manufacturers are leading the way in adopting predictive analytics due to its vast potentials. Look at some of the cases:

Defense & Aerospace: Predictive analytics facilitate complying with safety standards by predicting which components might fail, thus enhancing operational reliability.

Automotive sector: Predictive analysis is used by automotive producers to improve the supply chain and to react on demand changes within the shortest time possible.

Consumer Products: Businesses rely on predictive analytics to manage inventory better so that stock can satisfy demand.

The benefits of predictive analytics are numerous and its adoption has profound implications for businesses and industries. As shown in the examples, predictive analytics help resolve complex issues while enhancing efficiency. This technological evolution presents an opportunity to improve operations as well as overall business outcomes.

| Sector | Application of Predictive Analytics | Key Benefit |

|---|---|---|

| Aerospace | Forecasting component failures | Enhanced safety and compliance |

| Automotive | Optimizing supply chain operations | Improved production timelines |

| Consumer Goods | Inventory management based on demand | Reduced inventory costs |

Challenges of Implementing Predictive Analytics

It’s evident that alongside the benefits of predictive analytics, there are other complex challenges that need to be effectively addressed. One such challenge is the inadequately defined, or poorly organized data, which makes predictive modelling nearly impossible. In comparative analytics, as in any analytics, a manufacturer’s data cannot only be correct; it has to be complete, too. Moreover, many manufacturers tend to avoid the spend purely because of the bleed-off related to the training, hardware and software that is the baseline of automating predictive analytics systems. However, such expenses are often recovered in the future because of enhanced capacity of operations, which is what the business needs.

Conclusion

The appearance of predictive analytics denotes a significant change in the area of manufacturing. Manufacturers can now utilize analytics to operate at peak efficiency, lower costs, and maintain quality as never before. These innovations mark further strides in the industry which will surely be welcomed. Predictive analytics will help companies deal with problems, enhance their internal processes, and improve their brand image. The use of predictive analytics goes beyond satisfying immediate needs but rather emphasizes achieving long-term goals in a difficult economic environment.

Frequently Asked Questions

What is predictive analytics? Predictive analytics is the application of statistical algorithms and machine learning to historical data in order to predict future occurrences.

How does predictive analytics benefit manufacturers? It increases efficiency while decreasing costs and enhancing product quality by delivering insights needed to make more informed decisions.

What are some real-world examples of predictive analytics in manufacturing? Predictive analytics is used in forecasting, maintenance scheduling, and inventory control in aerospace, automotive, and consumer goods industries.

What challenges might manufacturers face when implementing predictive analytics? These include issues with data quality, the necessity for new technologies, and the integration of predictive models into existing workflows.

Is predictive analytics suitable for small manufacturers? Although the upfront cost may be daunting for small manufacturers, tailored approaches and stepwise adoption allow businesses of all sizes to utilize predictive analytics.

Comments are closed.